Carbide Inserts are replaceable bit that is used in a Cutter for working on different alloys such as Cast Iron, Aluminium, Steel in CNC Machines / Lathe Machines/ Milling Machines (Computerised Numerical Controlling Machine). The main advantage of Carbide Insert is it works faster and that result in more finishing of the Components.

But people often get confused while choosing the correct carbide insert as it comes in different size, style, grade, geometry, angel, specification, and these grade, specification , size are encoded in its Product Code kind of Random collection of Letters and Numbers.

We will decode the mystery of these codes of Carbide Inserts.

You must have heard of carbide insert comes with a unique code TNMG160408 CNMG120408 CCMT09t304 VBMT160404 , you must be thinking what are these codes to do with insert specification.

After reading this Blog Carefully you will be able to understand

What is specific insert specification?

What is insert angel?

What is insert grade?

What is insert full form?

How to check insert chart?

What is insert Geometry and dimension?

Inserts are used for different application like Boring, Turning, Curve, Grooving, Milling Etc. Every insert codes has its meaning in itself , Now we will go step by step and understand the decoding.

Just to start we will take an example of a Turning Insert CNMG120408-CQ.

- First letter denotes Shape of Insert.

- C means Rhombic – T Means Triangular, R means Round. ( See Chart Below)

- It help you to choose insert as per your Turning Application

- Second Letter Stand for Relief Angle of Insert

- C Means 7 Degrees – D means 15 Degree – N Means 0 Degree (see Chart Below)

- N is also called Negative Insert which can be used both Side. Its used for Less Finishing Requirement

- Which are not N are also called Positive Insert, and can be used only one side. Its used for High Finishing Requirement.

- Third Letter denotes tolerance of Insert Size. (see the Chart Below)

- Least to bothered about.

- Its size is in micron and doesn’t impact the component at significantly.

- Fourth Letter denotes Profile and if there is Hole in Insert.

- CNMG has Hole , TPKN doesn’t have Hole and so on.

- It also tells about its Hole Angle and Blade Profile.

- Fifth Letter denotes length of Insert on one Side.

- Length is in Milimeters.

- See the Chart Below.

- Sixth Letter Shows Thickness of Insert.

- Thickness is in Milimeters.

- See the Chart Below.

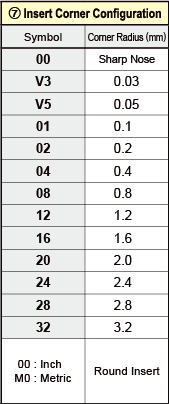

- Seventh Letter Shows Corner Radius of Insert.

- Usually Choosen by Choice of Application.

- Most Standard comes in 0.4 MM, 0.8 MM, 1.2MM.

- See the Chart Below.

- 8th and 9th Letter are Two Alphabet Combination.

- These are not ISO Standard.

- It varies from Manufacturer to Manufacturer.

- It denotes that Insert is Chip Breaker.

- Chip Breaker means breaking the Material being Machined. (See Image below)

- If its not present that means insert is not a Chip Breaker Insert.

- Its Absence is rarely happen until its a Cast Iron, PCD, or CBN Insert.

- There are many type of Chip Broker main two are Roughing and Finishing.

Now you can easily answer the question like

What is CNMG, TNMG, VNMG, WNMG, APMT, RPMT insert Grade, Angel, Specification, Dimension, Full form, Geometry, chart.

What is Turning, Milling , Grooving, Threading insert Grade, Angel, Specification, Dimension, Full form, Geometry, chart.

So, How was the Decoding, didn't you find it simple, even if you have any doubts , Please reach out to us at Hello@jaibros.com. Our Technical Team will assist you to make the selection easily.

2 comments

Thank you very informative

Best identification chart found on the web